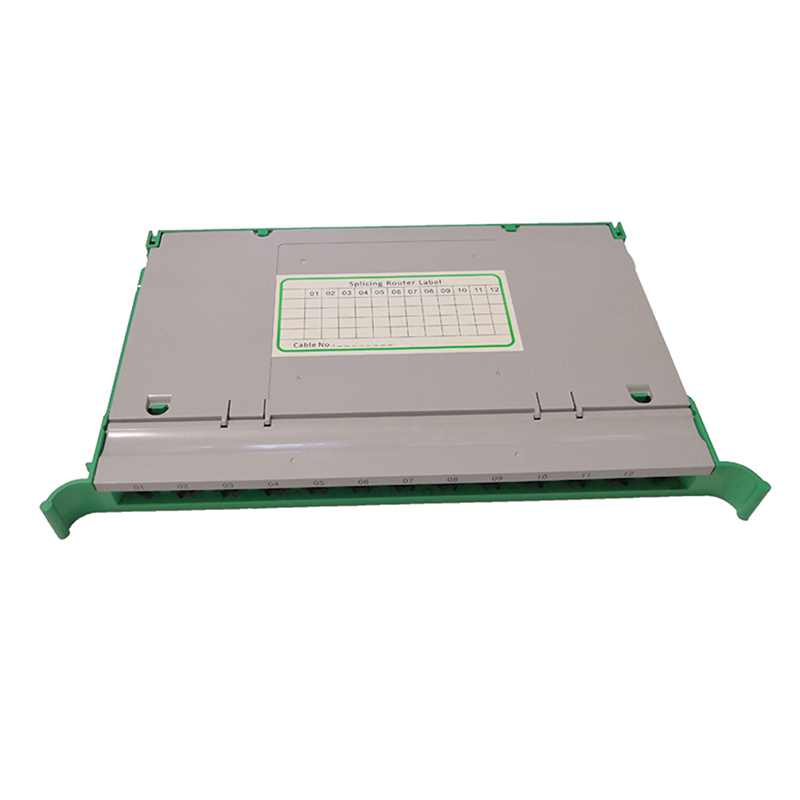

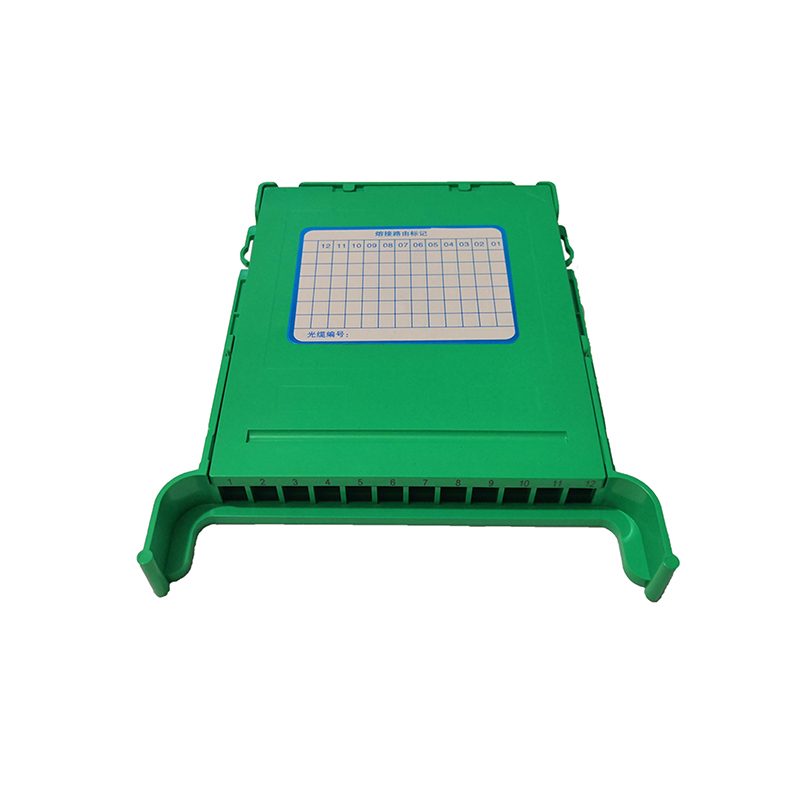

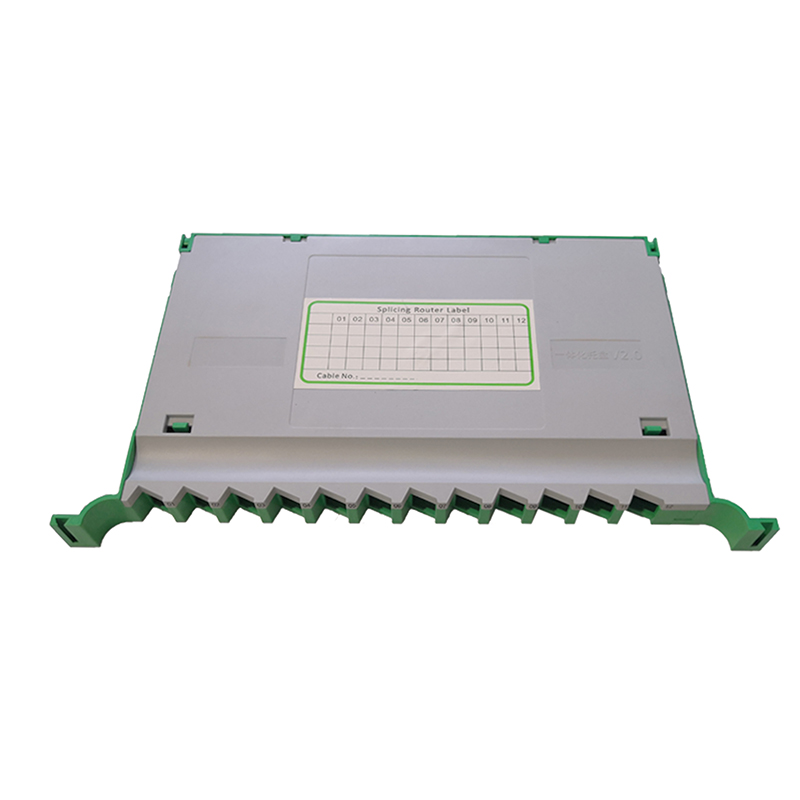

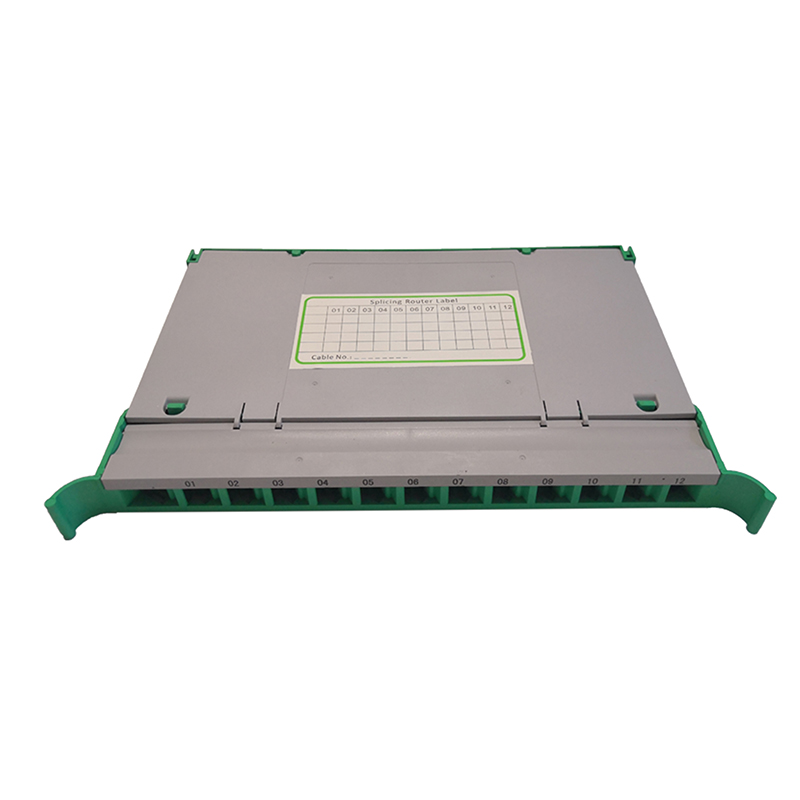

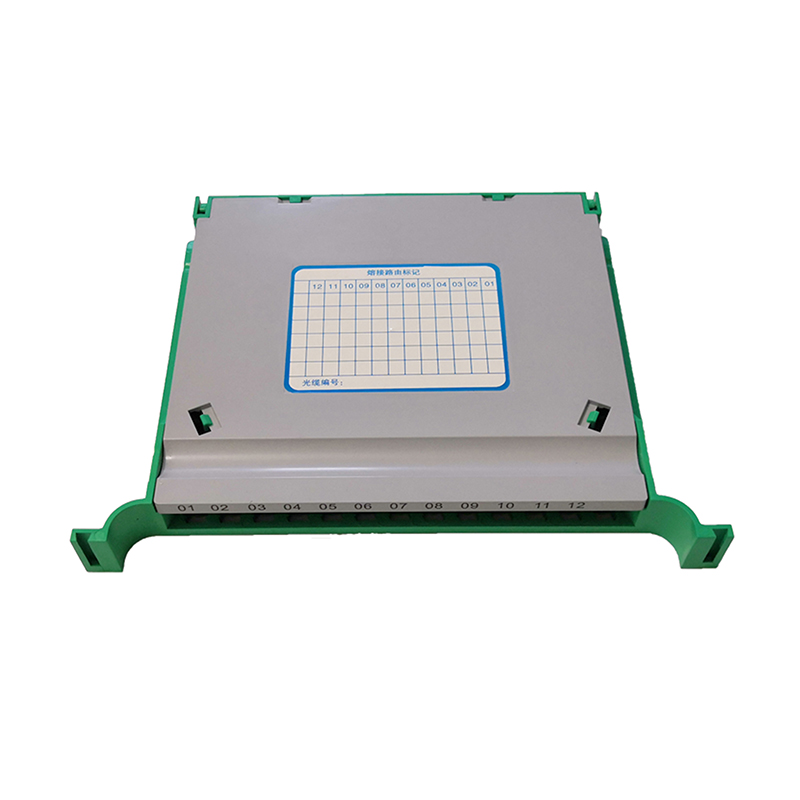

Product structure

1, the module is truly full-frontal operation, without the need to flip the module, you can realize the welding and winding of the optical fiber, smooth wiring, reliable protection, clear identification.

2, the integration module is a three-layer structure, the bottom layer is the wiring tray, the middle is the welding plate, the top is the cover plate, welding, wiring integration, more convenient maintenance.

3, the external fiber can enter the module from left or right respectively, and the storage space is large;Add a special cable ring for easy pulling out and inserting of the welding disc.

4, can be used at the same time FC, SC, LC three adapters, add an attachment can be installed ST adapter;

5, suitable for bundle and ribbon cable.The bending radius of an optical fiber must be greater than 40MM.The front side of the adapter and the connecting unit is at a 30° oblique Angle, which not only ensures the bending radius of the jumper, but also avoids laser burns to the human eye.

6. The capacity is 12 cores per disk. The pigtail and optical cable tube have their own cable channels, which are managed by layers to effectively protect the optical fiber from damage.

Technical characteristics

1, material: flame retardant ABS engineering plastic.

2, color: distribution panel, welding panel for telecom green, cover plate for gray 427U.

3, flame retardant: flame retardant level V0 (UL94 standard).

4, electrical strength: ≥3KV(DC)/1min no breakdown, no arc;

5, insulation resistance: ≥1000MΩ/500V(DC);

6, life: ≥1000 times.

The working environment

3, working temperature: -5℃~40℃.

4, relative humidity: ≤85% (30℃)

5, atmospheric pressure: 70~106Kpa

Installation and configuration

1. Integrated fiber fusion module 1 disk

2. Install 1 pair of pulling guide rails.

3, over the line ring 1.

Product specifications

1. Capacity: 12 cores

2, size: length 288mm* Width 180mm* height 25mm